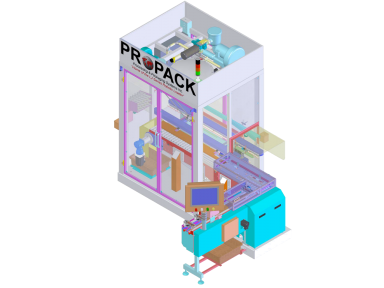

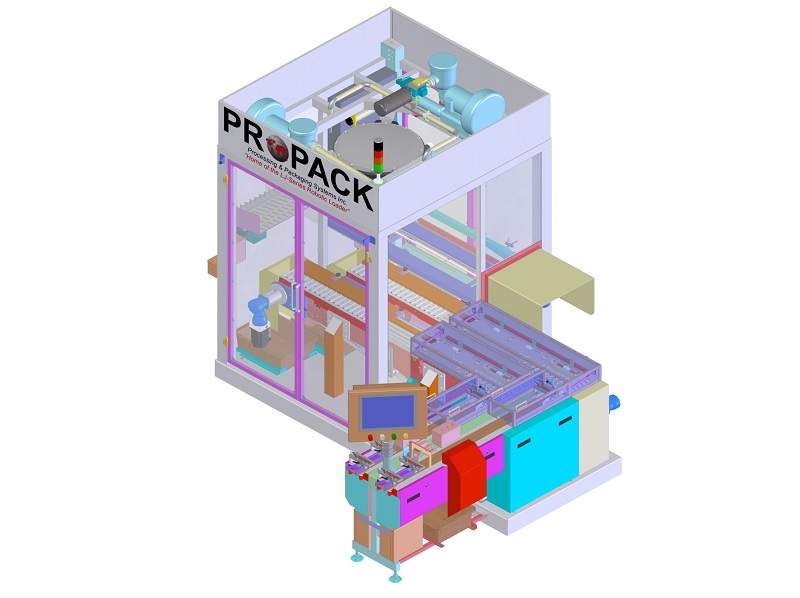

Propack provides customised robotic packaging solutions for a wide range of applications, requirements and package styles. We tailor our systems to optimise productivity, uptime and total cost of ownership (TCO).

We manufacture high-speed pick-and-place systems for food industry applications involving items such as cakes, cookies, candy, granola and snack bars.

Our robotic packaging systems are flexible and designed to handle package styles such as trays and cartons in single or dual-lane configurations.

Versatile robotic loading solutions for packaging applications

Propack robotic loaders are customised to fit specific applications while providing you with high-quality flexibility, reliability and performance.

Benefits of our robotic loading solutions include:

- Easy operation via simple operator interface

- Increased uptime

- Fast, repeatable size changeovers

- Sanitary, flexible design that can accommodate various package sizes

- Low operating costs

Capable of handling up to 900 incoming cartons, Propack’s robotic loading solutions feature a servo-driven, lugless carton management system for accurate carton positioning.

It also enables you to perform quick and easy recipe-driven changeovers, simple integration with most flow-wrappers and quick, no-tool changeover for product buckets or carton size adjustments.

Its cantilever-designed infeed conveyor facilitates the belt removal process, while its product-spacing reject system removes double packs.

High-speed carton and tray loaders

The LJ-DUAL is an efficient, resilient carton-loading machine that is designed to handle output from two medium-speed flow-wrappers.

The robotic top loader accurately collates products and load into cartons, trays or multipacks. Depending on the characteristics of the product, the LJ-TRT DUAL robotic top loader can operate at speeds of up to 1,200 products per minute.

Flexible robotic top loaders

The LB-SRT robotic collator and robotic carton and tray loader provides you with a cost-efficient, flexible carton and tray loading machine.

Highly automated, it is ideal for handling output from medium to high-speed flow-wrappers.

For vertical applications, the LJ-TRT top loader combines high-speed automation flexibility with a cost-efficient, robust carton loading machine.

It is suitable for handling material from medium to high-speed flow-wrappers.